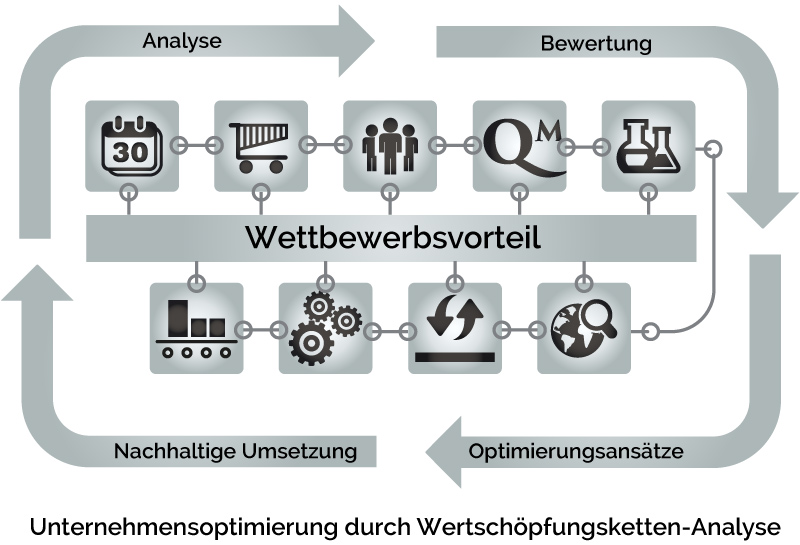

Value chain analysis

Analysis of the added value of your business activities

Sustainable corporate optimisation

Analyse fields of action

Food Resource Management is an experienced specialist in the critical analysis of complex value chains. We analyse all relevant fields of action step by step. This enables you to accurately evaluate your corporate activities with regard to the effectiveness and efficiency of the value-added processes, to tap unused potential and resources and to realise a cost advantage in the market. We develop implementation-oriented, holistic and process-oriented concepts for you to increase your overall efficiency and, if desired, accompany you during their implementation.

Areas of application

Added value through process optimisation

From reducing the use of raw materials by optimising strategic or operational purchasing or increasing productivity by increasing machine availability to eliminating bottlenecks by analysing weak points in the production process. Our results help you in the context of strategic decisions and secure your competitive advantage in the market.

- Cost and schedule controlling

- Key figure management and control

- Personnel costs / productivity

- Receivables and liabilities

- Sales deductions

- Examination of the material costs

- Designing the purchasing strategy (operational and strategic)

- Supplier evaluation

- Negotiation of prices and conditions

- Tendering of new contracts

- Design and conclusion of contracts

- Review of staff qualification

- Staff scheduling

- Outsourcing of service areas

- Development of performance-related key performance indicators

- Coaching and temporary staff management

- Staff turnover, sickness rate

- Audits, HACCP, certifications (IFS, BRC, Kosher)

- Complaints, traceability

- Analysis of waste quantities

- Use of rework

- Implementation of step controls

- Analysis of blockages

- Conceptual hygiene tours

- Cross-divisional coordination of development activities

- Development of new products

- Expenditure evaluations for developments

- Project and investment cost planning

- Analysis of the productivity ratios

- Evaluation of downtimes

- Review of set-up and cleaning times

- Optimisation of the employee deployment rate

- Bottleneck evaluation

- Evaluation of material usage rates

- Project management / project control

- Planned maintenance system

- Repair and investment plans

- Economic efficiency calculations

- Consumption of operating materials

- EDP-controlled or chaotic warehousing

- Reduction of partial deliveries

- Optimisation of stock levels and capacity utilisation

- Optimisation of fleet costs

- Reduction of acceptance refusals

- Optimisation of outsourcing costs

- Analyse der Geschäfts- und Marketingstrategie

- Entwicklung eines Vertriebs- und Marketingkonzeptes

- Sortimentsstraffung und Lieferfähigkeit

- Optimierung des Produktportfolios

- Erstellung von Marketingplänen

- Sustainable optimisation of packaging and packaging processes

- Specialist in the management of industrial data communication

- Partner for restructuring and project management

- Optimal production processes in costs and efficiency

- Preparation of a business valuation in which we present your company in clear terms and with meaningful figures. A presentation of strengths and weaknesses from the external perspective of experienced experts.

- We arrange value chain analyses, real estate and acquire equity capital.

Efficient value chain analysis

Analyse fields of action

- With an analysis of your value chain, you can closely examine your business activities in terms of effectiveness and efficiency of the flow processes.

- Food Resource Management is an experienced specialist in the critical analysis of complex value chains.

- We analyse all relevant fields of action step by step. We record your resources, present you with possible optimisation approaches and, if desired, accompany their implementation: from reducing the use of raw materials by optimising strategic or operational purchasing or increasing productivity by increasing machine availability to eliminating bottlenecks by analysing weak points in the production process. Our results help you in the context of strategic decisions and secure your competitive advantage in the market.

- “The only constant in the universe is change.” Heraclitus of Ephesus, (c. 540 – 480 BC), we work with you to develop optimal solutions and support you reliably and competently in the implementation of projects at both strategic and operational levels through holistic management.

- We know the markets and the new technologies and focus on innovative and practical advice. Convince yourself!

We open up new solution spaces and perspectives

Food Resource Management is an internationally operating specialist for professional management in the food industry.

With our following core areas, we cover the complete range of consulting-relevant topics in the food industry:

-

Interim Management

Vacancy Bridging and Restructuring

-

Project Management

Realisation of your projects in planning, implementation, management and control

-

Business valuation

Analysis and evaluation of your company structures

-

Value chain analysis

Analysis of the added value of your business activities

-

Company succession

Initiate the continuation of your business wisely

-

Change Management

Planned management of change processes from the actual to the target state

-

Leadership development

Empowering your leaders to be accountable and making that visible through results

-

Business Mediation

Conflicts are opportunities -tools for avoiding conflicts in your company

-

Set-up time reduction

In 8 steps to set-up time 0

-

Lean Management

Reduce costs sustainably to increase company profits

In accordance with our principle “Every customer is unique” we develop optimisation approaches together with you and accompany their implementation on request: from reducing the use of raw materials by optimising strategic or operational purchasing or increasing productivity by increasing machine availability to eliminating bottlenecks by analysing weak points in the production process. Our results help you in the context of strategic decisions and secure your competitive advantage in the market.

Solutions for demanding tasks

Case studies from practice

Example 1

Analysis of the value chain in the largest slaughterhouse in Ethiopia (project duration 12 months)

The slaughter rate for European cattle is about 80%, whereas in Ethiopian slaughter culture it is only 42%. Through coordinated training measures, the slaughter rate could be increased by 25% in a first step. As a result, meat from Ethiopia is now more competitive in international trade.

Example 2

Analysis of the value chain in a factory for processing bamboo into floor coverings and toothpicks in Ethiopia (project duration 3 months)

Bamboo has a possible water content of more than 80% after water storage. Since this raw material is paid for by weight, it is often watered by suppliers to the bamboo processing industry. For the production of flooring or toothpicks, however, the water content alone must not exceed 8%, which is achieved by using complex steam drying technology. Furthermore, by implementing water testing procedures for bamboo, it was possible to prevent the water content from rising above 30% before delivery. The operating result was improved by 17% through the reduction of energetic steam drying and the 40% reduction in the use of raw materials.

Example 3

Outsourcing of the packaging and shipping department at a bakery manufacturer as part of the value chain analysis and personnel cost reduction (project duration 2 months)

At a bakery manufacturer, personnel costs amounted to more than 43%. In order to avert a pending insolvency, these had to be reduced by at least 10%. Since the previous logistics and shipping processes had proven to be unproductive, an external service company was founded and the logistics and shipping area was outsourced. In a first step, this resulted in a 7% reduction in personnel costs and plant productivity was also increased by 4%.

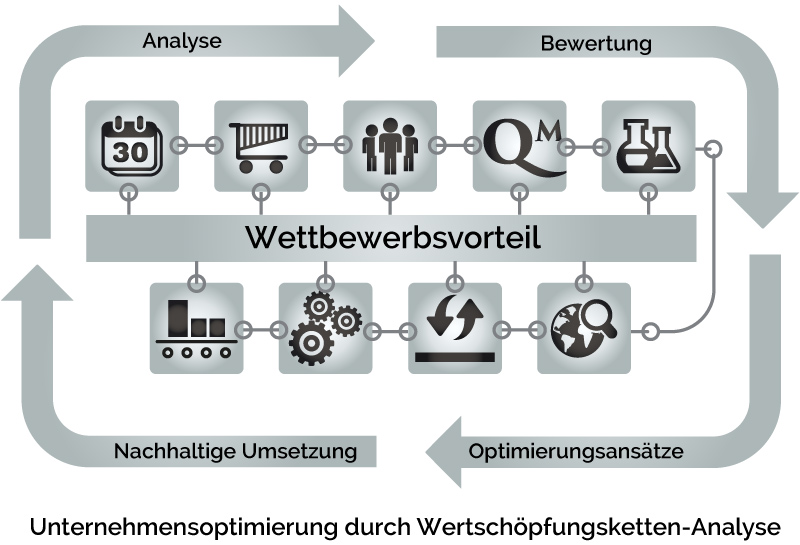

Value chain analysis

Analysis of the added value of your business activities

Sustainable corporate optimisation

Analyse fields of action

Food Resource Management is an experienced specialist in the critical analysis of complex value chains. We analyse all relevant fields of action step by step. This enables you to accurately evaluate your corporate activities with regard to the effectiveness and efficiency of the value-added processes, to tap unused potential and resources and to realise a cost advantage in the market. We develop implementation-oriented, holistic and process-oriented concepts for you to increase your overall efficiency and, if desired, accompany you during their implementation.

Areas of application

Added value through process optimisation

From reducing the use of raw materials by optimising strategic or operational purchasing or increasing productivity by increasing machine availability to eliminating bottlenecks by analysing weak points in the production process. Our results help you in the context of strategic decisions and secure your competitive advantage in the market.

- Cost and schedule controlling

- Key figure management and control

- Personnel costs / productivity

- Receivables and liabilities

- Sales deductions

- Examination of the material costs

- Designing the purchasing strategy (operational and strategic)

- Supplier evaluation

- Negotiation of prices and conditions

- Tendering of new contracts

- Design and conclusion of contracts

- Review of staff qualification

- Staff scheduling

- Outsourcing of service areas

- Development of performance-related key performance indicators

- Coaching and temporary staff management

- Staff turnover, sickness rate

- Audits, HACCP, certifications (IFS, BRC, Kosher)

- Complaints, traceability

- Analysis of waste quantities

- Use of rework

- Implementation of step controls

- Analysis of blockages

- Conceptual hygiene tours

- Cross-divisional coordination of development activities

- Development of new products

- Expenditure evaluations for developments

- Project and investment cost planning

- Analysis of the productivity ratios

- Evaluation of downtimes

- Review of set-up and cleaning times

- Optimisation of the employee deployment rate

- Bottleneck evaluation

- Evaluation of material usage rates

- Project management / project control

- Planned maintenance system

- Repair and investment plans

- Economic efficiency calculations

- Consumption of operating materials

- EDP-controlled or chaotic warehousing

- Reduction of partial deliveries

- Optimisation of stock levels and capacity utilisation

- Optimisation of fleet costs

- Reduction of acceptance refusals

- Optimisation of outsourcing costs

- Analysis of the business and marketing strategy

- Development of a sales and marketing concept

- Streamlining of the product range and delivery capability

- Optimisation of the product portfolio

- Preparation of marketing plans

- Sustainable optimisation of packaging and packaging processes

- Specialist in the management of industrial data communication

- Partner for restructuring and project management

- Optimal production processes in costs and efficiency

- Preparation of a business valuation in which we present your company in clear terms and with meaningful figures. A presentation of strengths and weaknesses from the external perspective of experienced experts.

- We arrange value chain analyses, real estate and acquire equity capital.

Efficient value chain analysis

Analyse fields of action

- With an analysis of your value chain, you can closely examine your business activities in terms of effectiveness and efficiency of the flow processes.

- Food Resource Management is an experienced specialist in the critical analysis of complex value chains.

- We analyse all relevant fields of action step by step. We record your resources, present you with possible optimisation approaches and, if desired, accompany their implementation: from reducing the use of raw materials by optimising strategic or operational purchasing or increasing productivity by increasing machine availability to eliminating bottlenecks by analysing weak points in the production process. Our results help you in the context of strategic decisions and secure your competitive advantage in the market.

- “The only constant in the universe is change.” Heraclitus of Ephesus, (c. 540 – 480 BC), we work with you to develop optimal solutions and support you reliably and competently in the implementation of projects at both strategic and operational levels through holistic management.

- We know the markets and the new technologies and focus on innovative and practical advice. Convince yourself!

We open up new solution spaces and perspectives

Food Resource Management is an internationally operating specialist for professional management in the food industry.

With our following core areas, we cover the complete range of consulting-relevant topics in the food industry:

-

Interim Management

Vacancy Bridging and Restructuring

-

Project Management

Realisation of your projects in planning, implementation, management and control

-

Business valuation

Analysis and evaluation of your company structures

-

Value chain analysis

Analysis of the added value of your business activities

-

Company succession

Initiate the continuation of your business wisely

-

Change Management

Planned management of change processes from the actual to the target state

-

Leadership development

Empowering your leaders to be accountable and making that visible through results

-

Business Mediation

Conflicts are opportunities -tools for avoiding conflicts in your company

-

Set-up time reduction

In 8 steps to set-up time 0

-

Lean Management

Reduce costs sustainably to increase company profits

In accordance with our principle “Every customer is unique” we develop optimisation approaches together with you and accompany their implementation on request: from reducing the use of raw materials by optimising strategic or operational purchasing or increasing productivity by increasing machine availability to eliminating bottlenecks by analysing weak points in the production process. Our results help you in the context of strategic decisions and secure your competitive advantage in the market.

Solutions for demanding tasks

Case studies from practice

Example 1

Analysis of the value chain in the largest slaughterhouse in Ethiopia (project duration 12 months)

The slaughter rate for European cattle is about 80%, whereas in Ethiopian slaughter culture it is only 42%. Through coordinated training measures, the slaughter rate could be increased by 25% in a first step. As a result, meat from Ethiopia is now more competitive in international trade.

Example 2

Analysis of the value chain in a factory for processing bamboo into floor coverings and toothpicks in Ethiopia (project duration 3 months)

Bamboo has a possible water content of more than 80% after water storage. Since this raw material is paid for by weight, it is often watered by suppliers to the bamboo processing industry. For the production of flooring or toothpicks, however, the water content alone must not exceed 8%, which is achieved by using complex steam drying technology. Furthermore, by implementing water testing procedures for bamboo, it was possible to prevent the water content from rising above 30% before delivery. The operating result was improved by 17% through the reduction of energetic steam drying and the 40% reduction in the use of raw materials.

Example 3

Outsourcing of the packaging and shipping department at a bakery manufacturer as part of the value chain analysis and personnel cost reduction (project duration 2 months)

At a bakery manufacturer, personnel costs amounted to more than 43%. In order to avert a pending insolvency, these had to be reduced by at least 10%. Since the previous logistics and shipping processes had proven to be unproductive, an external service company was founded and the logistics and shipping area was outsourced. In a first step, this resulted in a 7% reduction in personnel costs and plant productivity was also increased by 4%.